It has been a while since the NEWS has been updated but that does not mean that nothing has been happening. With the help of others, I will try to update what has been going on at the museum even though of late it has been snowy and cold. Thanks to Doug, Jeff and Mike for their photos.

It is October 25th, 2020, the last operating day of our pandemic shortened season. 715 rests down on the Track 2 platform waiting for passengers. Doug Rundell photo

It is October 25th, 2020, the last operating day of our pandemic shortened season. 715 rests down on the Track 2 platform waiting for passengers. Doug Rundell photo

The outside temperature was enough that the heat had to be turned on in 715. The museum is fortunate that the Car Department has been able to keep this important feature operable in the North Shore car as that is not the case in cars 20 and 304. Doug Rundell photo

The outside temperature was enough that the heat had to be turned on in 715. The museum is fortunate that the Car Department has been able to keep this important feature operable in the North Shore car as that is not the case in cars 20 and 304. Doug Rundell photo

A young visitor has discovered the signal cord as masked passengers and conductor Dan Kelly look on. Doug Rundell photo

A young visitor has discovered the signal cord as masked passengers and conductor Dan Kelly look on. Doug Rundell photo

Store manager Laura Taylor took the opportunity on the last operating day to pack up the store with the help of Janet Gonyo. Doug Rundell photo

Store manager Laura Taylor took the opportunity on the last operating day to pack up the store with the help of Janet Gonyo. Doug Rundell photo

Here is some of the merchandise stacked up on the baggage cart awaiting transport for the museum to off season storage. Doug Rundell photo

Here is some of the merchandise stacked up on the baggage cart awaiting transport for the museum to off season storage. Doug Rundell photo

I caught a view of the “reference” window in 4451 on November 11th as we were blessed with mild fall and early winter weather. Joseph Hazinski photo

I caught a view of the “reference” window in 4451 on November 11th as we were blessed with mild fall and early winter weather. Joseph Hazinski photo

By November 29th the temperature was getting lower and here we see a “tent” set up at the end of an empty looking 4451. Joseph Hazinski photo

By November 29th the temperature was getting lower and here we see a “tent” set up at the end of an empty looking 4451. Joseph Hazinski photo

Inside the tent we see Jeff Bennett assembling brand new, specially ordered heater strips on new brackets made up for us by our neighbor Leo Metz. Just assembling the strips and brackets took over three eight-hour days. Joseph Hazinski photo

Inside the tent we see Jeff Bennett assembling brand new, specially ordered heater strips on new brackets made up for us by our neighbor Leo Metz. Just assembling the strips and brackets took over three eight-hour days. Joseph Hazinski photo

With an electric powered radiator at hand, Jeff is now finally putting the heater strip assemblies into their housings. This had to be done carefully as each case holds one low heat and one high heat strip which have to be in the right position. Joseph Hazinski photo

With an electric powered radiator at hand, Jeff is now finally putting the heater strip assemblies into their housings. This had to be done carefully as each case holds one low heat and one high heat strip which have to be in the right position. Joseph Hazinski photo

On December 11th, Mike caught a photo of one of the Chicago Door and Window crew installing new siding on CA&E 316 after a complete new window sill had been installed on the west side. Mike Gilles photo

On December 11th, Mike caught a photo of one of the Chicago Door and Window crew installing new siding on CA&E 316 after a complete new window sill had been installed on the west side. Mike Gilles photo

Here is what 316’s side looked like on December 19th. It was too cold to prime but this is a step necessary for installing all the new side sash windows. Fortunately, we have a set of arch windows salvaged from Wheaton Shops in 1961 and the plan is to install them on the exterior of the car, back dating it properly to the early 1920’s era of the car’s existence. Mike Gilles photo

Here is what 316’s side looked like on December 19th. It was too cold to prime but this is a step necessary for installing all the new side sash windows. Fortunately, we have a set of arch windows salvaged from Wheaton Shops in 1961 and the plan is to install them on the exterior of the car, back dating it properly to the early 1920’s era of the car’s existence. Mike Gilles photo

On December 19th it was still warm enough for exterior body work to continue on 4288 as we see work being done to install a side sheet seam plate. Mike Gilles photo

On December 19th it was still warm enough for exterior body work to continue on 4288 as we see work being done to install a side sheet seam plate. Mike Gilles photo

We jump back to December 6th into 4451 as we see the heater units spread out on the floor. It turned out that wiring in the heaters needed to happen before the seat frames could be installed. The Monday crew did a good job of cleaning up and painting the metal heat deflectors that go on each seat with a heater, just one of the many tasks needed to complete this aspect. Joseph Hazinski photo

We jump back to December 6th into 4451 as we see the heater units spread out on the floor. It turned out that wiring in the heaters needed to happen before the seat frames could be installed. The Monday crew did a good job of cleaning up and painting the metal heat deflectors that go on each seat with a heater, just one of the many tasks needed to complete this aspect. Joseph Hazinski photo

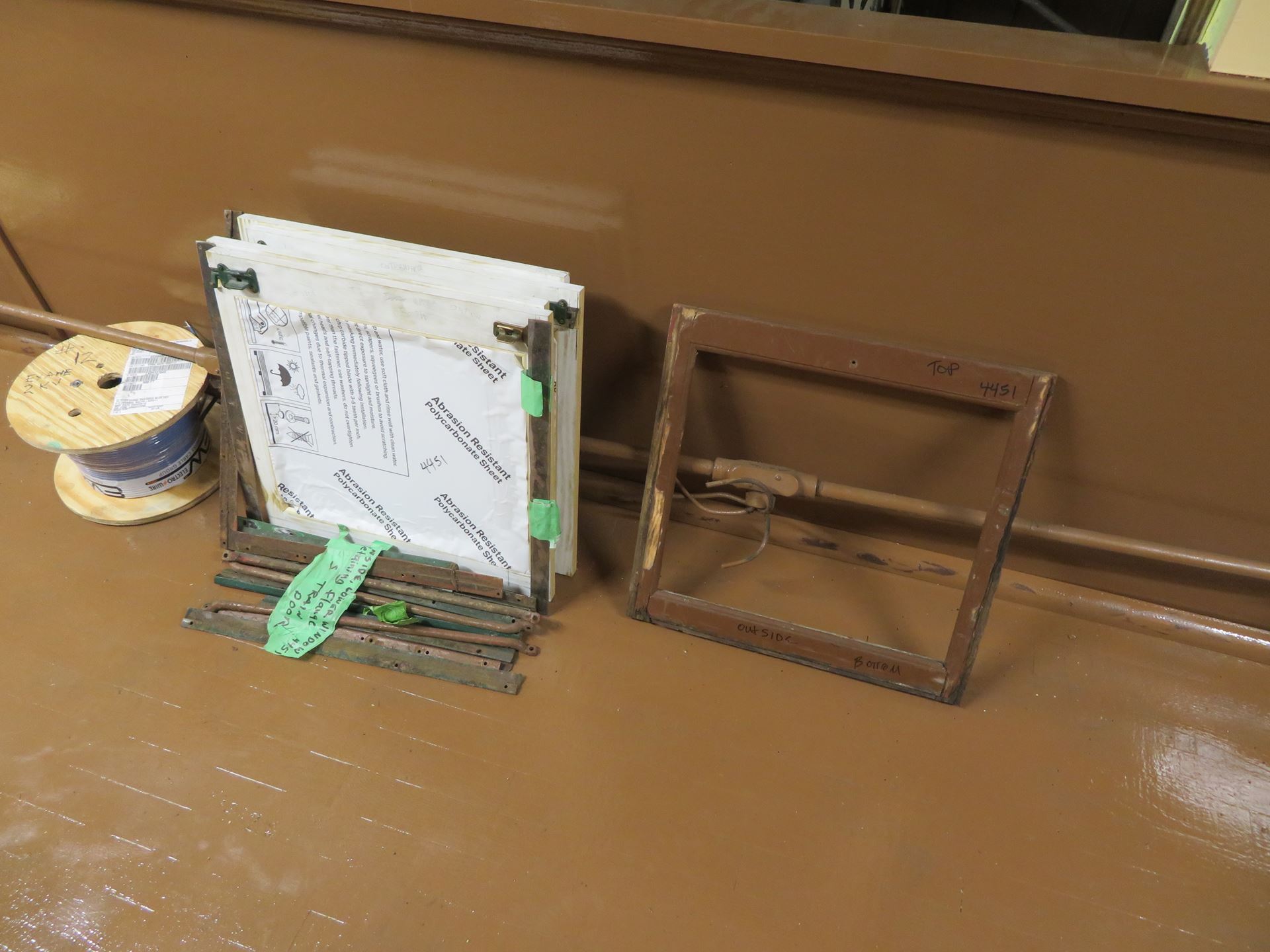

I also noticed that parts for the sliding windows in each train door at the ends of the car have been collected. Joseph Hazinski photo

I also noticed that parts for the sliding windows in each train door at the ends of the car have been collected. Joseph Hazinski photo

Back to December 19th daughter Rylee and her dad Jeff Bennett after careful measurement, are installing seat frames and then hanging the heater casings to the bottom of the frames. Mike Gilles photo

Back to December 19th daughter Rylee and her dad Jeff Bennett after careful measurement, are installing seat frames and then hanging the heater casings to the bottom of the frames. Mike Gilles photo

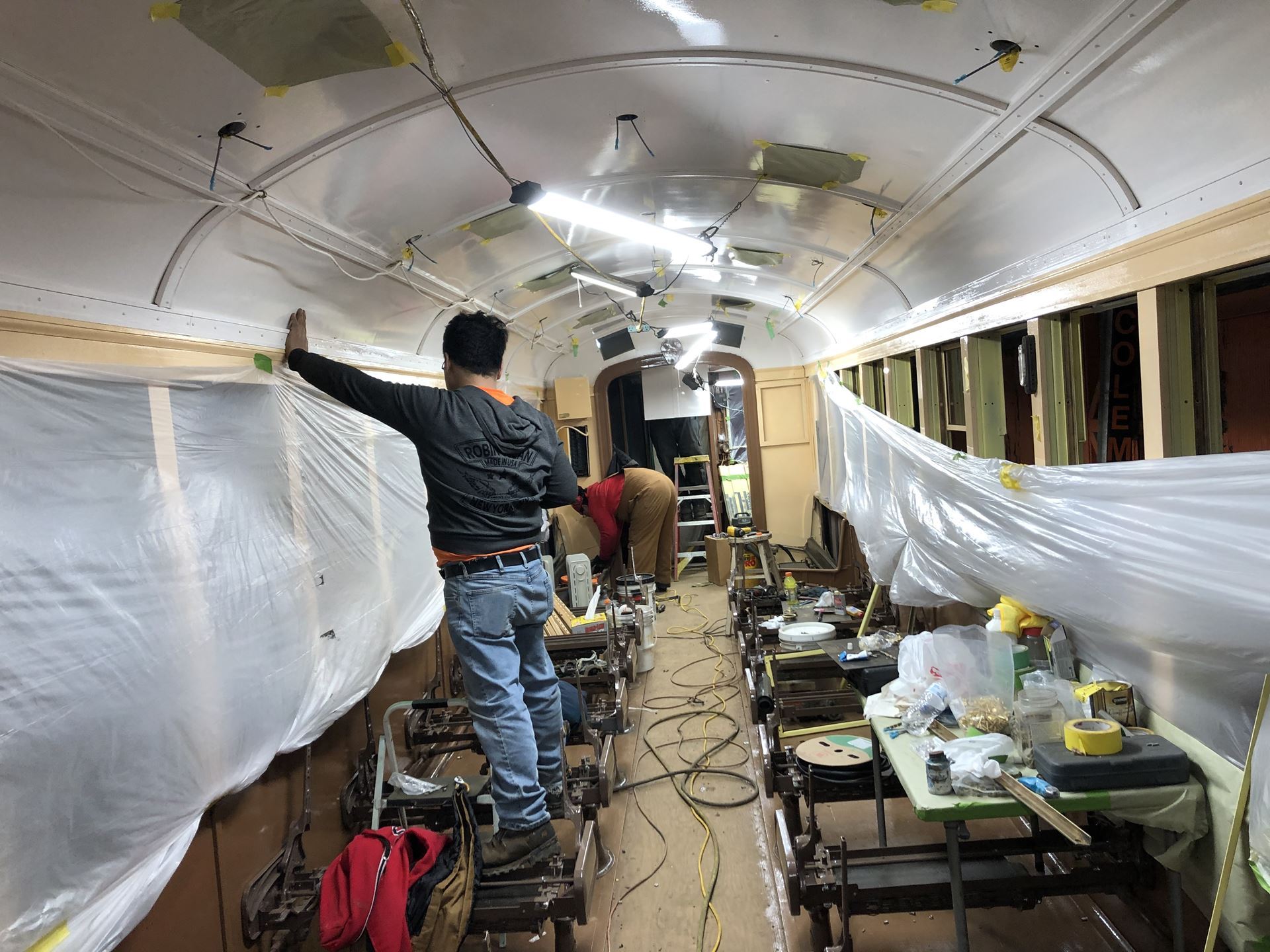

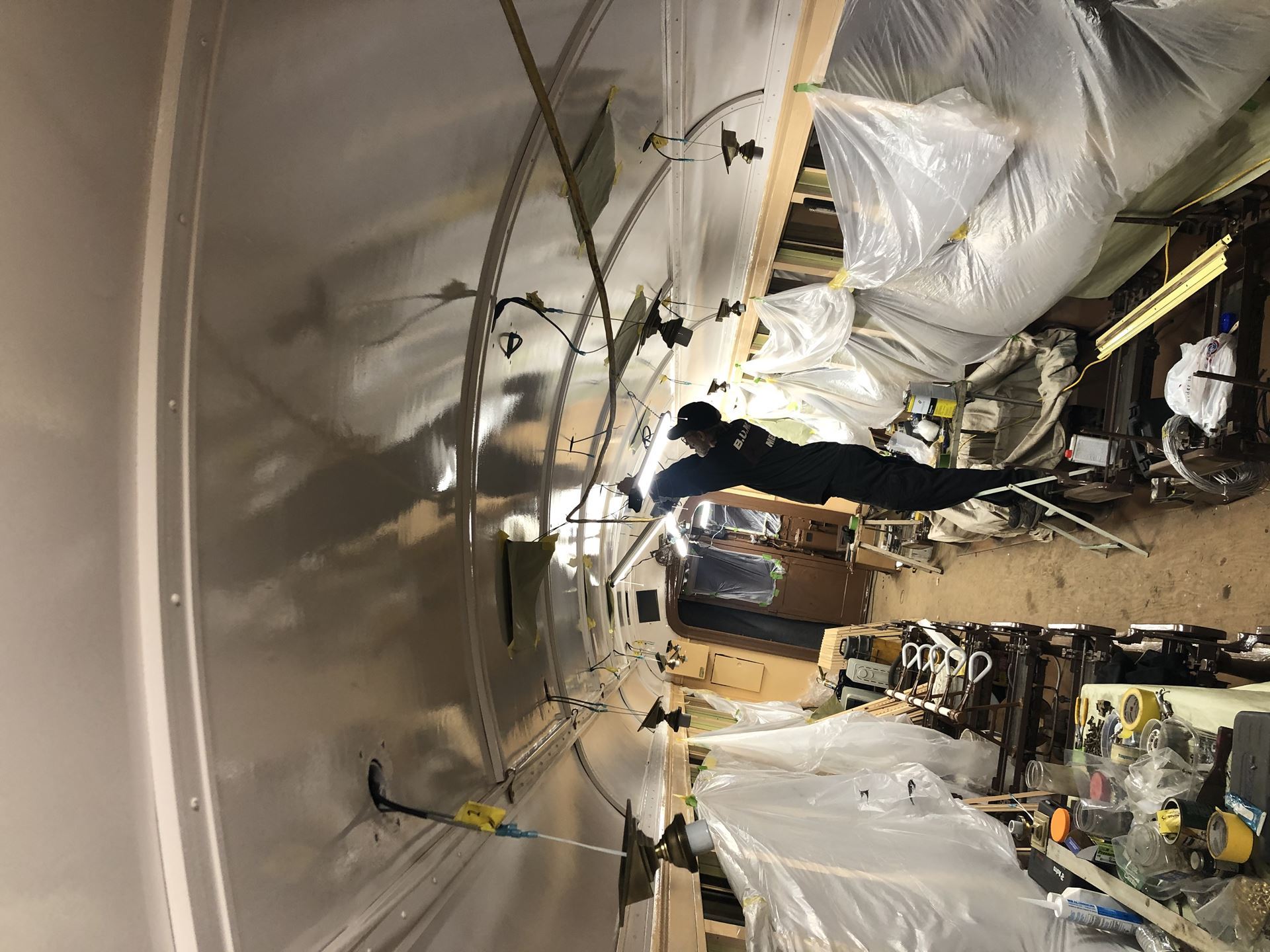

The next day we see the progress of the seat frame and heater installation on the weekend before Christmas. The plastic covering on the window openings helps keep the heat in, which is provided by the propane fired furnace Jeff has procured for just such service. Mike Gilles photo

The next day we see the progress of the seat frame and heater installation on the weekend before Christmas. The plastic covering on the window openings helps keep the heat in, which is provided by the propane fired furnace Jeff has procured for just such service. Mike Gilles photo

Here we have our contractor Kyle in Delavan in his shop showing off one of the window frames that he has stripped, primed and painted. Our crews disassembled all of the brass standee and opening sash windows before Jeff took them to Kyle. Jeff Bennett photo

Here we have our contractor Kyle in Delavan in his shop showing off one of the window frames that he has stripped, primed and painted. Our crews disassembled all of the brass standee and opening sash windows before Jeff took them to Kyle. Jeff Bennett photo

Because of water leakage over the years almost all of the window frames were split so Kyle revived the old art of lead repair to restore them using about 17 pounds of lead to do so. Lead once used as auto body filler before the advent of products like Bondo. A stack of completed frames are seen in the background. Jeff Bennett photo

Because of water leakage over the years almost all of the window frames were split so Kyle revived the old art of lead repair to restore them using about 17 pounds of lead to do so. Lead once used as auto body filler before the advent of products like Bondo. A stack of completed frames are seen in the background. Jeff Bennett photo

After the frames were finished in Delavan, off they went to LeWalt glass in Crystal Lake for glazing. Here we see Cliff assembling a window while Ken finishes up a piece of new glass. Fortunately, Ken had the right gasket material while Jeff was able to obtain all new screws and barrel bolts to assemble the frames. Jeff Bennett photo

After the frames were finished in Delavan, off they went to LeWalt glass in Crystal Lake for glazing. Here we see Cliff assembling a window while Ken finishes up a piece of new glass. Fortunately, Ken had the right gasket material while Jeff was able to obtain all new screws and barrel bolts to assemble the frames. Jeff Bennett photo

On December 27th we see the interior of 4451 with all of its walk over seat frames installed. Yes, the crew did take Christmas off! Mike Gilles photo

On December 27th we see the interior of 4451 with all of its walk over seat frames installed. Yes, the crew did take Christmas off! Mike Gilles photo

Berny Kamenear of the Monday crew developed a way of cleaning up the light fixtures on a drill press, using a brass wire wheel revealing the brass finish. Mike and Jeff cleaned renewed the actual bulb sockets, installing new wire leads for each fixture. Doug Rundell photo

Berny Kamenear of the Monday crew developed a way of cleaning up the light fixtures on a drill press, using a brass wire wheel revealing the brass finish. Mike and Jeff cleaned renewed the actual bulb sockets, installing new wire leads for each fixture. Doug Rundell photo

It is January 10th and Jeff is making up a test board to check the values need for a new battery charging resistor. The original one just fell apart when Jeff opened it up and this key component needs to function so the batteries can be charged as they provide the low voltage DC power for the control system, the emergency interior lights, the sensitive door edges, buzzer system as well as the headlight and marker lights at the #1 or front end of the car. After determining the proper values with the test board and consulting with Fred Lonnes, he was able to order the correct heating strips that are needed to make the charging system functional. Mike Gilles photo

It is January 10th and Jeff is making up a test board to check the values need for a new battery charging resistor. The original one just fell apart when Jeff opened it up and this key component needs to function so the batteries can be charged as they provide the low voltage DC power for the control system, the emergency interior lights, the sensitive door edges, buzzer system as well as the headlight and marker lights at the #1 or front end of the car. After determining the proper values with the test board and consulting with Fred Lonnes, he was able to order the correct heating strips that are needed to make the charging system functional. Mike Gilles photo

On January 23rd, Thee and John strung the conductor’s valve cord. The heaters have been tested and work fine after Jeff serviced and tested the relays and thermostat. In the lower right hand corner seat frame you can see one of the heat deflectors which is mounted above the heater case. While I have no photos, Fred Biederman has been gradually setting up each door engine, making them functional and connecting them to the sliding side doors. Mike Gilles photo

On January 23rd, Thee and John strung the conductor’s valve cord. The heaters have been tested and work fine after Jeff serviced and tested the relays and thermostat. In the lower right hand corner seat frame you can see one of the heat deflectors which is mounted above the heater case. While I have no photos, Fred Biederman has been gradually setting up each door engine, making them functional and connecting them to the sliding side doors. Mike Gilles photo

The next day Sunday, January 24th Barb Bennett, Jeff’s mom worked on final cleanup of the light fixtures in the warm confines of 4451. Mike Gilles photo

The next day Sunday, January 24th Barb Bennett, Jeff’s mom worked on final cleanup of the light fixtures in the warm confines of 4451. Mike Gilles photo

Also, on the 24th a number of standee windows were installed, the first rebuilt units going in. Mike Gilles photo

Also, on the 24th a number of standee windows were installed, the first rebuilt units going in. Mike Gilles photo

February 6th, one of Jeff’s employees, Sean Cross wires up a light fixture in 4451. Jeff Bennett photo

February 6th, one of Jeff’s employees, Sean Cross wires up a light fixture in 4451. Jeff Bennett photo

Mike Gilles and James Tarbet are busy at work inside of the heated 4451 in spite of the cold outside February 6th weather. Jeff Bennett photo

Mike Gilles and James Tarbet are busy at work inside of the heated 4451 in spite of the cold outside February 6th weather. Jeff Bennett photo

The fruits of his labor, in place window sashes, after Mike’s work to install them on the 6th. With the windows in place the plastic comes down from the open spaces. Jeff Bennett photo

The fruits of his labor, in place window sashes, after Mike’s work to install them on the 6th. With the windows in place the plastic comes down from the open spaces. Jeff Bennett photo

James Tarbet installs the door latch on one of the train doors as the effort to enclose 4451 goes on. Jeff Bennett photo

James Tarbet installs the door latch on one of the train doors as the effort to enclose 4451 goes on. Jeff Bennett photo

With the work lights turned off towards the end of the day all the light circuits are tested with 120-volt AC. And they all worked! The next step is to cover all the splices with heat shrink tubing and then fasten the fixtures to the ceiling. Jeff Bennett photo

With the work lights turned off towards the end of the day all the light circuits are tested with 120-volt AC. And they all worked! The next step is to cover all the splices with heat shrink tubing and then fasten the fixtures to the ceiling. Jeff Bennett photo

Jeff is coming down the aisle reviewing the progress of the day. Mike Gilles photo

Jeff is coming down the aisle reviewing the progress of the day. Mike Gilles photo

Jeff takes a selfie with the “reference window” just before it is to be removed from 4451. It was the only window to stay in place during all that work that has been done to the car to date. Jeff Bennett photo

Jeff takes a selfie with the “reference window” just before it is to be removed from 4451. It was the only window to stay in place during all that work that has been done to the car to date. Jeff Bennett photo

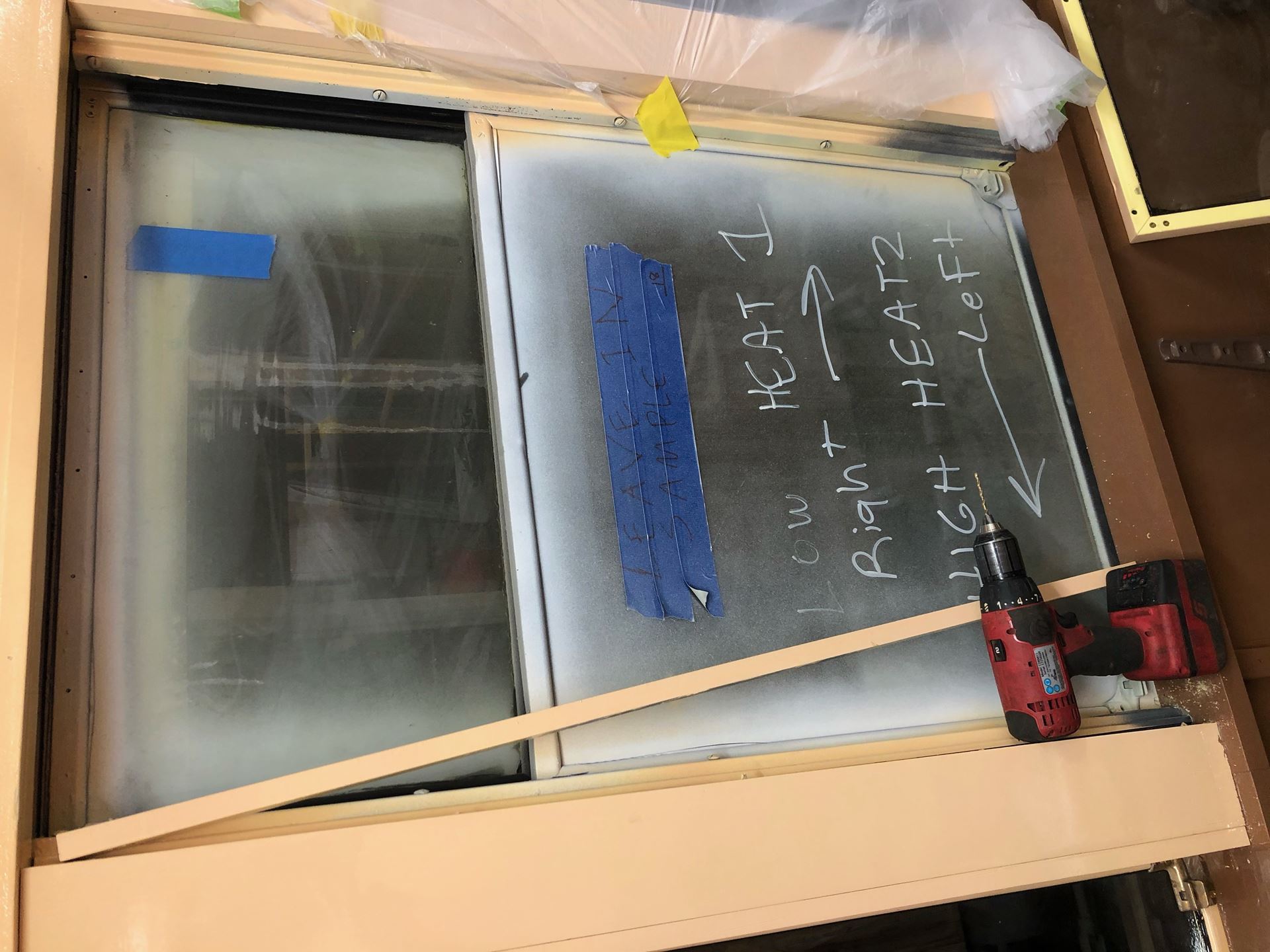

One more look at the “reference window” before it is to be removed and replaced with one of the rebuilt sashes. It had notes on it to assist in the reinstallation of the heaters and lights. Jeff noted it was a major milestone as now the air brakes, electric heaters and interior lights are now functional. Jeff Bennett photo

One more look at the “reference window” before it is to be removed and replaced with one of the rebuilt sashes. It had notes on it to assist in the reinstallation of the heaters and lights. Jeff noted it was a major milestone as now the air brakes, electric heaters and interior lights are now functional. Jeff Bennett photo

The next day February 7th, John and Thee install the second of four ceiling mounted handhold bars. Jeff Bennett photo

The next day February 7th, John and Thee install the second of four ceiling mounted handhold bars. Jeff Bennett photo

James Tarbet installs the latch to the second train door as work continues on Sunday the 7th. Jeff Bennett photo

James Tarbet installs the latch to the second train door as work continues on Sunday the 7th. Jeff Bennett photo

Mike and James continue with the window sash installation. There are several windows that will need some adjustment before they can go back in so 4451 is all but enclosed. Jeff Bennett photo

Mike and James continue with the window sash installation. There are several windows that will need some adjustment before they can go back in so 4451 is all but enclosed. Jeff Bennett photo

The crew continues to work on many tasks until it is time to quit for the day. Mike Gilles photo

The crew continues to work on many tasks until it is time to quit for the day. Mike Gilles photo

A satisfying look at the east side windows with a view to 316 out of them. Next up will be the special sign box windows at every corner. Jeff Bennett photo

A satisfying look at the east side windows with a view to 316 out of them. Next up will be the special sign box windows at every corner. Jeff Bennett photo

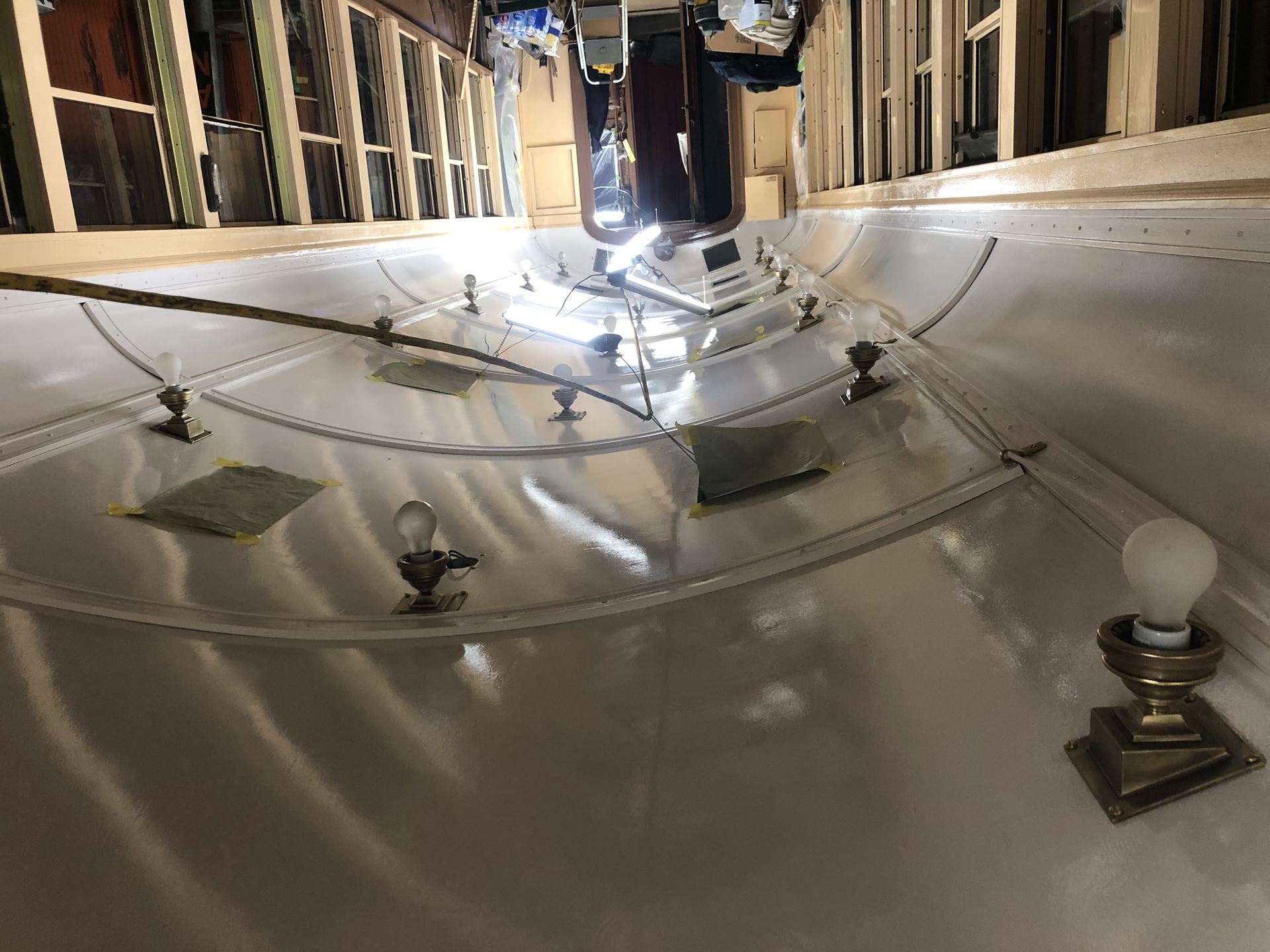

Now that all the wire splices have been heat shrink covered, all the light fixtures have been fastened to the ceiling with slotted screws. The regulators for the ceiling air vents are being cleaned up, repaired as needed and professionally refinished along with their paired exterior roof vents. Jeff Bennett photo

Now that all the wire splices have been heat shrink covered, all the light fixtures have been fastened to the ceiling with slotted screws. The regulators for the ceiling air vents are being cleaned up, repaired as needed and professionally refinished along with their paired exterior roof vents. Jeff Bennett photo

It is the end of the day on February 7th 2021 just before the lights are turned out. Much has been accomplished and work will continue with the goal of 4451 being ready for service in the Spring of 2021. Challenges remain but so much has been accomplished to date. Jeff Bennett photo

It is the end of the day on February 7th 2021 just before the lights are turned out. Much has been accomplished and work will continue with the goal of 4451 being ready for service in the Spring of 2021. Challenges remain but so much has been accomplished to date. Jeff Bennett photo